Commercial Remote Solar – South Sudan Project

17 Jul, 2014

16 kWp off grid power system for His House of Hope, South Sudan

THE CHALLENGE

His House of Hope is a remote hospital located in Yei, South Sudan. In September 2012 an Australian doctor and his family moved to South Sudan to work with another doctor on site and expand the hospital. The project brief sounded simple; find a way to provide a reliable power source for the hospital with minimal need for diesel, as diesel is not consistently available or affordable.

THE SOLUTION

Our first task included making contact with the doctor on site in Yei, to establish what they were using as power source, and establish what their current and future power needs would be. The current power system consisted of a diesel generator during the day which charged a small battery bank to provide some basic lighting at night. With the increase in power demands with the planned expansions of the hospital, we estimated the cost of continuing a diesel generator to cost the mission organisation around $21,000 per year. Further to this, the generator was very unreliable and provided very dirty power which was not going to be an option with the new hospital equipment. Based on the information provided from site we estimated an average requirement of 48kwh per day to run this hospital.

Due to the remoteness of the site we decided to complete the design, construction and pre commissioning here in Tasmania. The system also needed to be fully automated and able to be controlled and monitored from our office here in Tasmania. This would allow us to provide ongoing support off site, from our Tasmanian office.

MODE Electrical offered to donate all the consultancy, design, engineering, construction, and commissioning on site to the project. This left around $120,000 in costs for both the materials, and shipping the equipment to site. After applying to SMA, Germany for assistance, all the SMA equipment for the project was generously donated by this company. Many local Tasmanian individuals, businesses and churches donated money and other Australian suppliers offered discounts on products purchased. We also applied to the Australian Federal Government DAP (Direct aid Project), who donated a large sum to provide the remaining funds required.

We purchased a 40ft container to house and transport the system. We built a frame and wired up the battery bank into the container. The inverters, controls and switch gear were all mounted and wired up on a wall next to the battery bank. We fully tested the system here including automatic generator operation, remote monitoring and control. The container was packed up together with medical equipment and other supplies. It was then shipped over to Mombassa in Kenya by boat and then by land up to Yei, South Sudan. After many border crossings and typical third world traveling, it miraculously arrived on site in one piece.

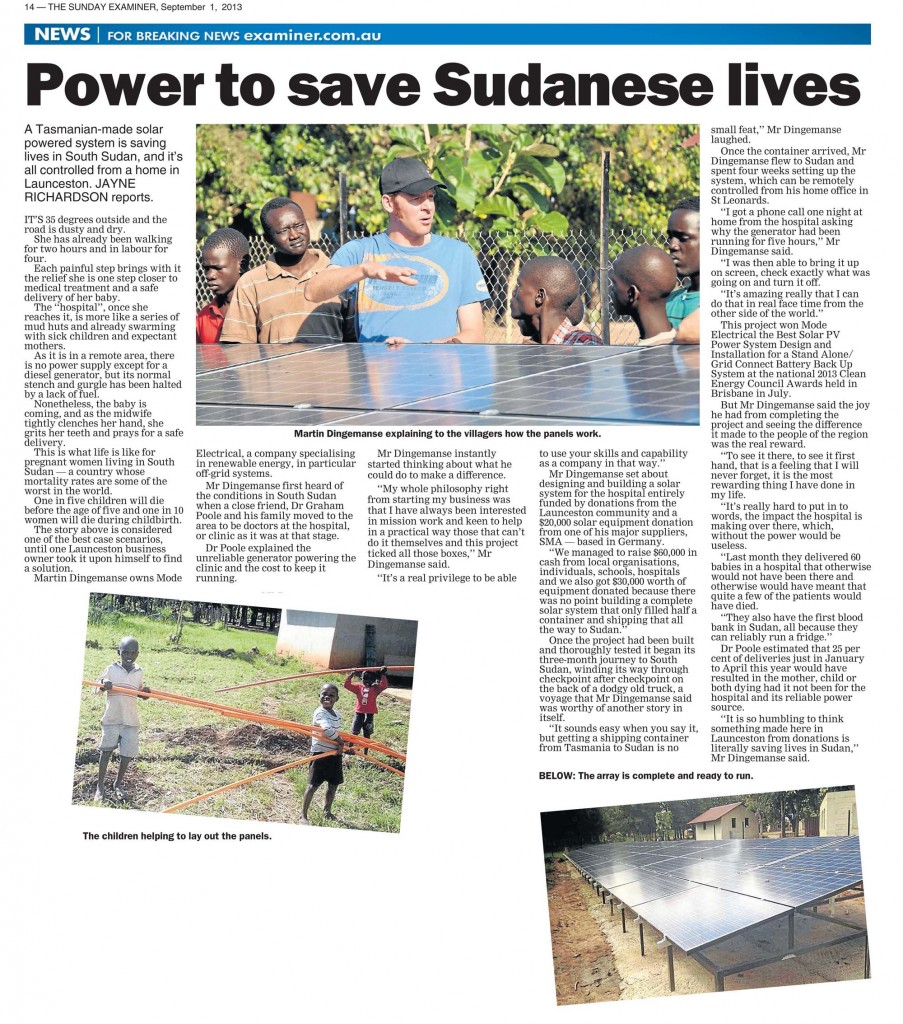

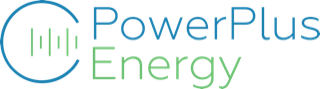

After the container had arrived at the Yei site, Martin traveled to Yei, to set up the system himself. Together with the help of the locals he constructed a ground mount frame to house the 64x 250w solar modules. The generator was set-up in a nearby shed. The remote monitoring was connected to satellite internet on the site. All 500m of trenching were dug by hand! As well as set up the solar system we ran new cabling to the hospital, nearby staff housing and kitchen.

THE SYSTEM

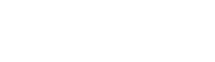

The basic system components included 2x SMA Sunny Island 5048 inverters, 2x SMA SMC 8000TL inverters, 64x 250w REC solar modules (on a ground mounted array), a Sonnenschein 2400ah@c10 48v gel battery bank, 12kva Kubota diesel generator with auto start, remote monitoring and system control. A 40 foot shipping container was proposed to be used to house the system as well as to transport it and other medical equipment from Australia to site.

THE RESULT

The system has now been up and running for over 3 years, and supplies all the power for the hospital with little need for the backup generator. The system also supplies power for staff housing, kitchen and a school, which was not in the original design brief, and produces an estimated 21,600 kWh of power per year.

With this extra load the generator runs a little more than it was designed to, but now the whole site benefits from a reliable 24/7 sustainable power supply. The generator is set to run at 80% of capacity to minimise diesel costs, rather than running a large generator all day, often at no load, like the old system. It is estimated to be a cost saving of $27,625 USD per year in diesel use.

We can be in our office in Tasmania and monitor, graph and change any part of the system. This system has also allowed the first blood bank in South Sudan to be established due to a reliable power supply.